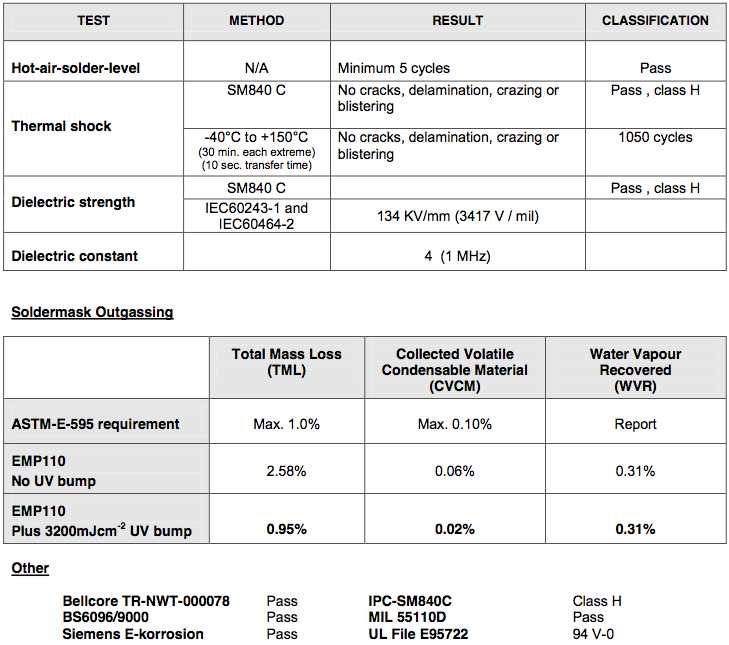

National Technologies uses Electra EMP 110 solder mask in both circuit board manufacturing facilities. It is a robust, photo-imageable aqueous processable material that meets or exceeds all industry requirements and standards.

Available in the following colors: Green,Blue, Red, Yellow,Black,White and Clear.

Our default standard is semi gloss green.

Carapace EMP110 has been used in the high volume production of PCBs since 1987. The Carapace family has been formulated to exceed the increasing demands of PCB processes, combined with a large process window.

Carapace EMP110 is a contact exposure, aqueous developing, liquid photoimageable soldermask, using two- component epoxy technology to give high levels of chemical resistance over copper, copper oxide, tin-lead or gold plated circuits. Due to their resolution capability, high dielectric strength and physical resistance properties

Carapace soldermasks are used as solder resists and insulation coverings on all types of printed circuits, particularly high-reliability, double-sided and multilayer, fine line, surface mount boards.